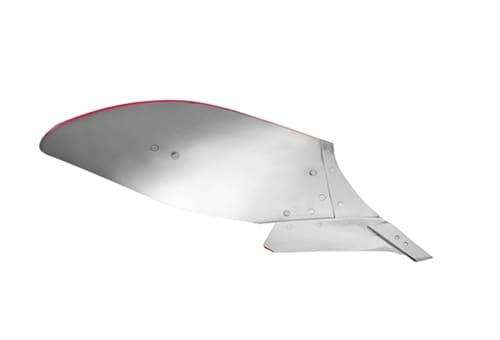

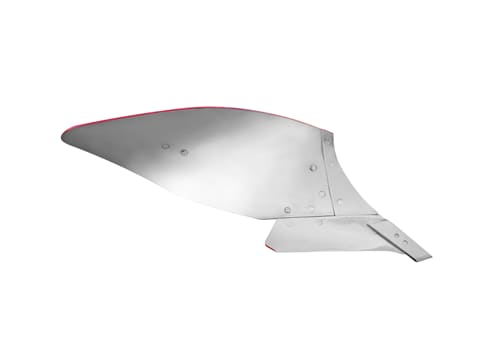

Kverneland 3400 B VARIOMAT

Plough | Reversible plough

High output for in-furrow/on-land operations and low costs of ownership

On-land & In-furrow New Generation of mounted reversible ploughs. Maximise output and ploughing performance 5 - 7 furrows

The advantages of this Reversible plough

- Easy swap In-furrow / On-land

- Ideal for tractors with dual wheels or rubber track

- Kverneland Trailer Transport Solution (TTS)

- Unique wheel memory system

- Smooth turnover action

- "4P" skimmers

Description

The New generation shearbolt model Kverneland 3400 B Variomat® is designed for a peace of mind: high performances via a simple set-up, unbeatable low cost of ownership, unmatched robustness. The Trailer Transport Solution “TTS” offers the optimum maneuverability during transport. In-furrow to On-land is easily achieved in 2 simple steps. The pulling line adjusts automatically for the correct alignment at any time (Kverneland Auto-line). Combined with the renowned low draft Kverneland bodies, the fuel consumption is kept to its minimum while the lifetime of parts is extended beyond expectations. The adjustable “4P” skimmers enable the perfect ploughing. Shearbolts fitted to new robust legs shear sharp under 5 ton of pressure to guarantee a quality ploughing.

The Kverneland 3400 B Variomat® offers comfort with lower lift requirements than other brands. The headstock No 300 provides the necessary strength for a smooth reversing. Robust frame 120 x 200 mm. In its on-land configuration, the plough’s impressive offset (up to 3,85 m) allows the tractor to be positioned exactly to the drivers’ requirements.

The peace of mind is also illustrated with the unique wheel memory system that maintains the desired furrow depth settings after the reversing cycle. Likewise, one can choose an automatic front furrow adjustment instead of the standard mechanical solution.

Efficient re-consolidation in one pass: Kverneland packers and packer arm compatible.

Highlights

- Easy swap from In-furrow to On-land operations. The driver has fingertip control

- Smooth turnover action thanks to an efficient parallel linkage system which hydraulically moves the plough into a balanced position

- Ideal for tractors having dual wheels or rubber track

- "4P" skimmers enabling easy adjustments in 4 Positions. For ex. quick working depth central adjustment.

- Optional automatic front furrow adjustment. Mechanical front furrow adjustment is standard

- Unique wheel memory system that maintains the desired furrow depth settings after the reversing cycle

- Safe transport: Kverneland Trailer Transport Solution (optional)

- Efficient re-consolidation in one pass. Kverneland packers and packer arm compatible

Features

Features

Kverneland Heat Treatment Technology:

- more than 140 years of experience

- steels that withstand the toughest of conditions

- best robustness/weight ratio on the market

- for equivalent robustness, competitors would add more steel and therefore more weight, quicker wear, dissappointing ploughing results

Kverneland Steels:

- Benefits from less weight:

easier to pull/lower fuel consumption/lower lift requirement/reduced wear and stress for the tractor/more economical … - Benefits from more resistance:

minimum breakage/less maintenance/lower rotation for wearing parts/time saving/highest 2nd hand plough value/longer life for the plough/more economical…

Problems always happen when the plough is being used, when the work must be done!

A Kverneland plough is a peace mind!

More info: Kverneland Technology

Excellent Ploughing Quality

They are renowned all over the world for their:

- excellent ploughing quality

- outstanding wear resistance

- low draft requirements

Bodies of a unique steel.

Kverneland Technology: 12 hours carburising heat treatment process for:

- optimum wear resistance (sharp as a diamond)

- the necessary flexibility to absorb impacts

Body No. 8 – “Universal body”

for light to heavy soils

good trash burial

easy pulling

Depth: 15 to 30 cm (6 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 9 – “Deep Universal body”

for heavier soils and deeper ploughing

well turned and packed furrows

easy pulling

Depth: 15 to 35 cm (6 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 28 – “Wide tyre body”

suits all soils; even heavier soils than body 8

very wide empty furrow for tractor wheels up to 710 mm

good turning and well packed

easy pulling

suitable for Depth: 12 to 30 cm ( 5 to 12”)

Width: 30 to 55 cm (12 to 22”)

Body No. 30 – “Finger body”

for sticky-stony soil and abrasive soils

good work in heavier soils

best crumbling effect

wide furrow bottom,

Depth: 20 to 35 cm (8 to 14”)

Width: 30 to 55 cm (12 to 22”)

Body No. 34 – Plastic mouldboard

Long and slim shape (similar to body 28)

For soils with high humus content without stones

Advised for tactors with large tyres

Easy pulling

Working depth: 12-35cm

Working width: 30-55cm

Landside / mouldboard: 40 degree

Body No. 38

universal body – easy to pull

for any soil conditions

recommended for tractors with large tyres

from deep to shallow ploughing

perfect turning of the furrow slice

working depth: 12-35 cm

working width: 30-55 cm

landside / mouldboard: 40°

Body No. 40 – “Finger body”

easy to pull finger body

identical shape to body No.38

for wet, sticky, abrasive stony conditions

recommended for tractors with large tyres

crumble effect. Market furrows at low speed (winter ploughing)

working depth: 12-35 cm

working width: 30-55 cm

landside / mouldboard: 40°

Importance of heat treatment

- The frame is an essential part of the plough construction. For Kverneland quality standards, a non heat treated part is a weak part!

- Kverneland frames are heat treated by induction twice. The temperature transfer to the steel is closely monitored. The frame gains 3 times as much strength. This unique Kverneland induction processes provides robustness and flexibility while ensuring an outstanding durability.

Stronger but not heavier

- For the equivalent Kverneland robustness, competitors would use more steel in thickness or in dimensions, therefore producing a heavier frame.

- Heavier frame impacts negatively pulling forces, wearing of parts, lifting capacities, tractor life time, and fuel consumption.

Long lasting

- Weldings are also a critical weakness for a plough frame. Kverneland frames are supplied as one sole part!

Unbeatable in stony conditions !

Kvernelands fully automatic non-stop Auto-Reset System is unbeatable when it comes to trouble-free ploughing in stony conditions. The clever multi-leaf spring system allows the plough legs to release over stones and other solid objects in a smooth and efficient manner. This avoids sudden jolts and possible damage. Once the obstruction is passed, the plough body automatically returns to the correct ploughing depth.

Safety compliance

With today's demands for higher output, both tractor and plough are expected to perform quicker than ever. This makes more arduous demands on the equipment, particularly on the safety systems designed to protect tractors, ploughs and drivers against the dangers encountered whenever the plough meets hidden obstructions in the ground. The Kverneland Auto-Reset system guaranties this safety high standars requirements.

Adaptable to varying soil conditions

Depending of the type of soil all Kverneland ploughs can be equipped with different leaf springs packages. For soft soils, a normal spring with 5 leaves is the best choice to obtain the perfect ploughing in stony conditions. Today, most Kverneland ploughs are delivered with the Heavy Duty springs package (HD) with 7 leaves. This will perform well in most conditions. If the soil is very hard and stony - a double leaf spring package is recommended.

Extra leaves when needed

The standard Auto-Reset system includes 7 Kverneland heat treated springs (640Kp).

For heavier to extreme soil conditions, extra leaf springs are added for up to 1400kp.

The leaves are easily fixed with one central bolt only.

Individual body release !

The Kverneland mechanical Auto-Reset system enables very plough body to release independently. A quality ploughing is therefore guaranteed.

Minimum wear and high second hand value

Kverneland's Auto-Reset System is a quite simple construction that withstands the punishing forces year in, year out, with a minimum of maintenance. Save time and money !

Moreover, the Kverneland auto-reset system guarantees a longer life to the plough. When hitting an obstacle, the pressure on the point, frame, plough parts, decreases. The stress on Kverneland ploughs is therefore reduced. Consequently, second hand Kverneland ploughs sell at a higher value than competitors ploughs.

*by using an Hydraulic system, pressure would increase

Technical specifications

Technical specifications

Download brochure| Model | 3400 B Variomat | |

|---|---|---|

| Interbody clearance cm | 85/100 | |

| Head- stock | Nº 300 | |

| Type of beam | Shearbolt | |

| Working width cm | 30-50/35-55 | |

| Underbeam clearance cm | 80 | |

| No. of furrows | 5, 5+1, 6, 6+1, 7 | |

| Weight (kg) 5 furrows | 2040 | |

| Weight (kg) 6 furrows | 2248 | |

| Weight (kg) 7 furrows | 2456 | |

| Lift requirement (kg) 5 furrows | 6100 | |

| Lift requirement (kg) 6 furrows | 7000 | |

| Lift requirement (kg) 7 furrows | 8500 |